Production Ability and Process

Morelux has perfect production and pro- cessing equipments for the aluminum lighting pole. By the end of 2014, More- lux will have 6 spinning machines, auto- matic welding machine, powder coating line, bending machine, cutting machine, 13-meter anodizing line and so on.

These bring an annual production capacity of 80000 nos aluminum lighting poles. We can not only produce garden pole, but also road pole, flag pole and traffic pole. Perfect production management system can guarantee the quality of aluminum lighting pole in the production, and the variety of shapes can meet the different requirements of customers.

Aluminum Pole Production Process

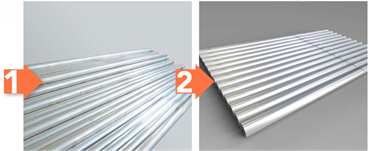

Raw materials for spinning are aluminum alloy 6063/6060 tube. It is an excellent aluminium alloy widely used for the construction of aluminum windows and doors, curtain wall frame, with high level wind resistance pressure, assembly performance, corrosion resistance and decorative properties.

Through large full CNC spinning equipment, raw materials are made into conical or profiled bar in the process of high speed spinning. All the poles do not allow longitudinal welding line, and it requirements smooth lines and excellent roundness.

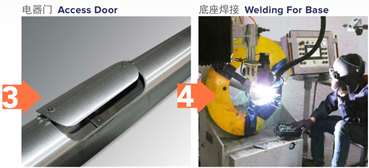

Each pole has a junction box for electric door installation. Morelux adopts advanced cutting equipment to cut the hole door, the door becomes a part of the rod body, ensuring the waterproof of electric door. we use allen key to protect the door, mean time we welding workpiece “L” for the grounding wire.

The base using A356 low pressure casting, and T6 heat treatment, we use automatic welding equipment to connect base and pole. The welding quality has the Canadian welding Bureau certification. In this high quality welding process, the welding strength and beauty are guaranteed.

Heating in the 185-195 temperature interval 7-8 hours to make the rod body molecular structure

tends to be stable, the hardness reaches 9-11HW.

Before Surface Finishing, We can polish the pole in different thickness to fit customer requestment.

We have four finishing for aluminum poles as following:

1. Anodizing

anodizing is an electrochemical mothod which creates an oxide layer on the surface of the matel,which is suitable for coastal corrosion areas or salted areas.The standard anodizing coating is 15um,but we can do better according to customer’s require.

2. Fluorocarbon coating

A new coating material,it has excellent anti-fade,anti-air polluted(acid rain) corrosion,anti-UV ability.

3. Powder coating

Colored polyester powder coating,it has bright color,anti- ultraviolet radiation,non-fading.

4. Water transfer printing

Through the water pressure to make the wood design enclosed on the pole surface.

Notice: Anodizing inherently results in color variation on aluminum as the material difference between the poles,the base and the welding material,it is inevitable.if you want to ensure the color onsistency on surface of poles.powder coating or fluorocarbon coating is recommended.

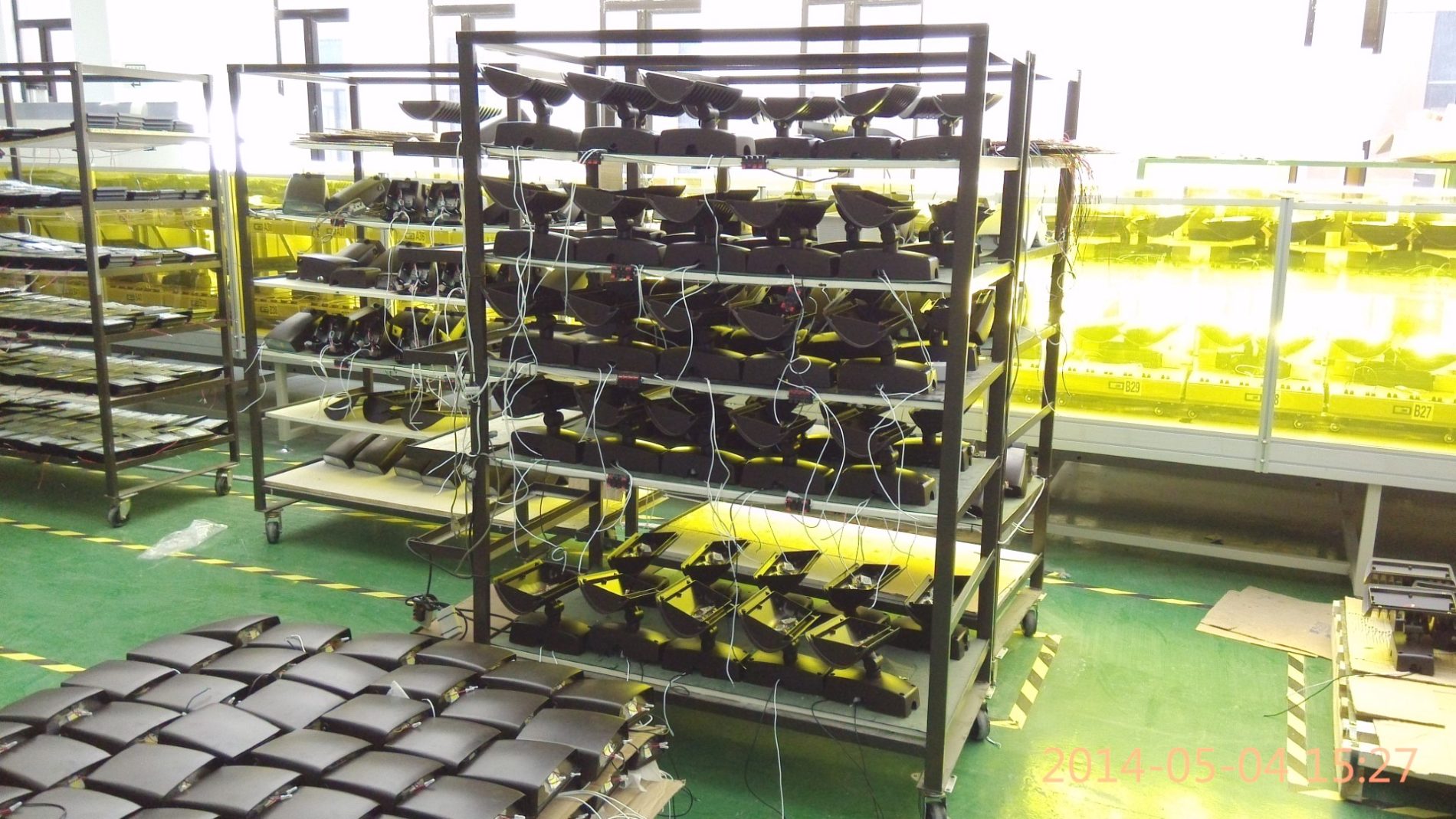

Morelux has complete testing equipments especially for the poles, brakets and accessories. Our inspection including: tensile testing, yield strength test, ductility test, oxidation/spray film thickness test, adhesion test, hardness test, the base of mirror image analysis and testing. ensuring the quality of each aluminum poles. mean time, morelux imported a spectrometer can have determination of aluminum materials, constitute a chemical element, compliance with international standards.

Morelux use reinforcement nylon bag, bubble bag and corrugated packaging multilayer light pole, three layers of packaging can be carefully protected to ensure the lamp post, lamp post not to be damaged in transportation.